NRE, with its strong roots and broad diversity, has remained a global leader in the rail transportation industry for years and remains at the vanguard despite recent market volatility. No matter the industry’s ups and downs, NRE has remained and will remain steady and successful, with diverse business strengths to rely on.

NRE designs and manufactures new locomotives from the ground up, and re-engineers used locomotives to give them new life.

NRE buys used locomotives and re-engineers them for sale and for lease, and services and maintains locomotives, including an extensive global field service network.

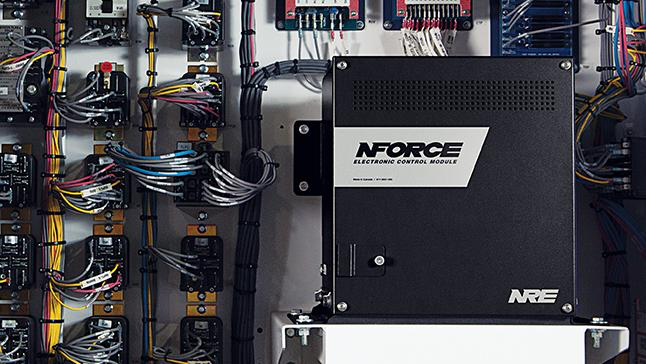

NRE manufactures and supplies parts to the locomotive market, and designs and manufactures electronic control and propulsion products to the rail industry.

“NRE started as a service business,” said Mike Zerafa, NRE’s AVP of North American Sales and Business Development. “Then, over time, it really got focused on new locomotives. With the market today as it is, we’ve gone back to our roots, and we’re doing a lot more service, component rebuilds, parts, and locomotive rehab.”

During 2017, NRE performed extensive locomotive service work in both the Class 1 and Short Line/Regional Railroad markets.

“We assisted customers in getting their locomotive fleet back in operation with minimal downtime,” Zerafa said. “NRE is a value-added, full-service provider with technical expertise and systems integration.”

NRE has also made recent inroads in the mass-transit segment of the industry, providing the services and machinery that keep people moving.

NRE received a significant number of orders from the transit segment in 2017, including an overhaul and upgrade of six GP40-2 locomotives that included engine upgrades to T0+ emission standards and to -3 technology, utilizing NRE’s NFORCE microprocessor that improves tractive effort and locomotive reliability.

NRE was awarded more than 40 engine overhauls by the transit segment, including NRE emission-certified 645T0+ engines. These engine rebuilds met the strict requirements of Buy America, a federal requirement that “steel, iron and manufactured goods used .. are produced in the United States.”

Transit companies are also fans of NRE’s Tier 4 switchers, which offer proven green technology. “Commuters like to buy our Tier 4 switchers because they’re very emissions conscious,” said Steve Sonni, Senior Account Executive. “NRE has the only Tier 4 switcher that is ARB-verified, which makes this locomotive eligible for grants, local or national.”

The NRE Tier 4 switcher has also been a product of choice for Amtrak, as well as the military, which has purchased more than 25 units from NRE over the last four years.

In 2017, NRE won multiple orders for the True Switcher, 2GS14B N-ViroMotive locomotives built on SW-type switcher frames.

The GenSet N-ViroMotive locomotive was developed and designed by NRE between 2001 and 2005 in response to the California Air Resources Board more stringent environmental regulations. The first engine went into service in 2007. Today there are more than 300 N-ViroMotives in service throughout the world.

“NRE has the True Switcher, a Tier 4 locomotive with our 600 horsepower (1GS) and 1200 horsepower ARB-verified switcher, retrofitted to EMD SW 1200 or 1500,” Sonni said. “NRE has been successfully providing switchers with this technology for more than a decade.”

NRE has also stayed on the cutting edge of railroad electronic technology with its 2017 launch for production of the NRE Electronic Actuator. After successful service testing with a number of customers, NRE began making a plug-and-play replacement for the mechanical hydraulic Woodward PGR governor.

“The NRE Actuator mounts in the engine compartment using the existing mechanical actuator mounting position,” said Zerafa. “The Actuator is oil-free, eliminates the need for a load regulator and is a single-module design that can directly replace the PGR governor on a stand-alone basis or be further integrated using communications to the locomotive control system.”

During 2017, NRE also installed several NRE-added value packages to older locomotives such as the GP7/9 or GP38/40’s, upgrading them to perform with 20-30% improved adhesion, greater reliability and improved diagnostics capability.

“The NFORCE systems come with optional, integrated, idle-limiting control that reduces fuel consumption and exhaust emissions,” Zerafa said. “Also available as part of the upgrade is the NCORDER Event Recorder.

“Our Tier 0+ certified engine rebuilds offer lower emissions and improved fuel economy,” he said. “All of these upgrades can be made to customer-owned locomotives or the extensive NRE used-locomotive inventory, available for immediate sale or lease.”

Also in 2017, NRE accepted a contract to modernize some heavy, four-axle, shunting locomotives for Slovenia Railways and simultaneously launched NRE’s EU-compliant propulsion system with IGBT technology.

The auxiliary drives of the class 642 and 643 Slovenian locomotives were replaced by electric ones, and new diesel engines with appropriate cooling, exhaust and fuel systems were installed. The diesel engines are modern railway duty engines, MTU models 12V 1600 R50 rated exhaust emissions standards (IIIB). NRE’s NFORCE microprocessor, developed for locomotive control, was also added.

NRE isn’t alone in its positive outlook. The rail transportation industry performed well in 2017 after struggling for the past couple of years, according to Zacks Equity Research.

“The 29.3% improvement in the Dow Jones U.S. Railroads Index on a year-to-date basis bears testimony to bullishness surrounding railroads,” the company reported recently.

NRE remains the world’s largest independent supplier of locomotive servicing and field services, new and remanufactured locomotives, and locomotive leasing and salvage. NRE manufactures and supplies locomotive parts, including state-of-the-art electronic and propulsion controls, and emission and fuel-saving technologies.