If you’re looking for new equipment, but you need an economical option, NRE has you covered with the largest inventory of secondhand locomotives in the market to buy or lease. But that’s only half of the story.

The other half are the reasons that you’ll be so happy with your choice. It’s called NRE-added value and it comes with every NRE product and service, from the sale of a new fleet of locomotives; to helping that customer who calls, after hours, about a broken part; to buying an NRE Qualified/Rebuild locomotive.

The NRE-added value starts with sales and customer service, the representatives who answer your call, and will continue to provide solutions throughout your business dealings with NRE.

“We are always available,” said Kirby Roseveare, NRE’s Vice President of International Sales. “Our sales reps provide solutions for our customers; they become an extension of their businesses. That is what separates NRE from our competitors.”

NRE team members bring an average of 20 years’ experience in the industry to their work — expertise that can’t be matched. And because they make the parts they use, the company has a broader area of expertise. That’s NRE-added value.

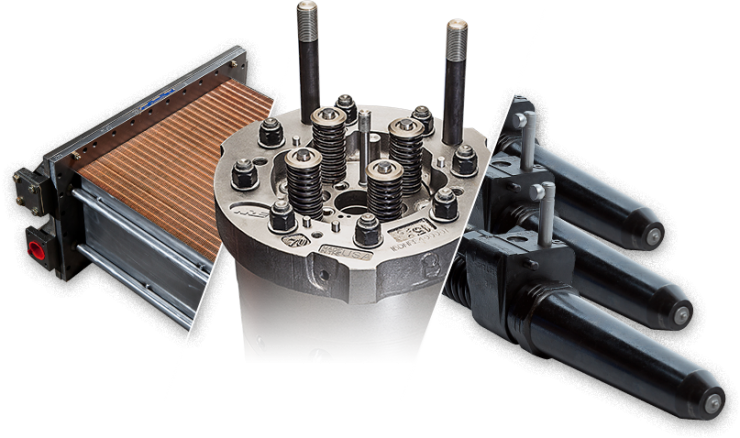

“Unlike a lot of locomotive parts suppliers, we’re also a locomotive builder, so we consume most of the components, whereas our competitors just buy and sell, and have no idea if the parts work or fit,” Roseveare said. “There’s a level of expertise here at NRE.”

Once you’ve made the decision to buy or lease a Qualified locomotive from NRE, you can count on compliance with Federal Railroad Administration regulations.

“Parts are changed as needed to bring the locomotive within Original Equipment Manufacturer specifications as well as customer requirements,” said Richard Elgin, Senior Technical Specialist. “This is common practice for the NRE lease fleet.”

If you choose a Qualified/Rebuild locomotive, you can have absolute confidence in the product because of NRE’s strict specifications. That’s NRE-added value.

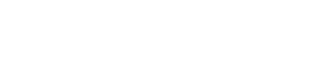

“NRE Rebuild specifications are tighter than the OEM specifications,” Elgin said. “We manufacture and rebuild most of the components in house under our Quality Assurance system. NRE is certified by the Association of American Railroad (M-1003) and the International Organization for Standardization (ISO 9001:201).”

You can also be assured that NRE’s Qualified/Rebuild locomotives meet or exceed the latest emissions standards. That’s because NRE manufactures the most current emission Tier kits, yet another NRE-added value.

Once you’ve chosen a locomotive, you’ll have a smorgasbord of options to tailor your “new” equipment. Those options are a big part of the NRE-added value of your purchase.

“NRE-added value can include locomotive upgrades with NRE-engineered and manufactured systems that modernize the equipment, improving performance and emissions,” said Mike Zerafa, AVP of North American Sales and Business Development. “Some of these packages can include microprocessor control or emission upgrades.”

All of those NRE high-tech add-ons were designed, built and tested in-house.

“We can retrofit a locomotive’s original control system, which could have been built in the ’50s, ’60s or ’70s,” said Steve Sonni, Senior Account Executive. “Essentially we strip those old systems out and put in our own microprocessor control system, NFORCE. It modernizes the performance and the efficiency of the locomotive.

“We have a lot of electronics available for locomotives that do specialty things,” said Sonni. “We have GPS electronic systems. We have NLIMIT, our automatic engine start and stop electronic system. We design and build all this at our NRE Calgary division.

“NRE Rebuilds are reliable. They work all of the time, and they increase the performance of the locomotive” said Sonni. “And you can change the specifications to make it more to your liking. You may want a new air-conditioning system. You may want a different kind of control stand. You may want to incorporate a new positive train control system. You get the opportunity to modernize and customize your locomotive.”

And when you need a part or have a question, you’ll have the NRE-added value of the Technical Assistance Line (618-NRE-HELP), providing answers 24 hours a day; NRE’s worldwide sales and customer service staff, and the NRE Field Service Team, standing ready to help with any mechanical issues.

Customers aren’t just numbers at NRE.

“They’re a name and a face to us,” Sonni said. “And we treat them accordingly.”

NRE’s diversified portfolio of products and services helps keep prices competitive. The quality of NRE’s products and services helps keep customers happy. But it’s the NRE-added value that sets this company apart and helps keep NRE a global leader in the rail, marine and power industries.