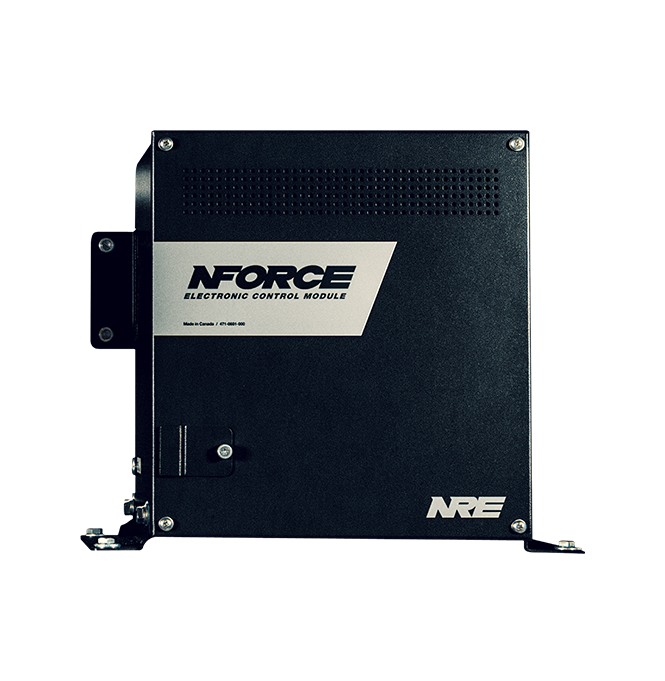

NFORCE

Upgrade your locomotive control system...

New locomotives manufactured today feature improved adhesion, greater reliability, better diagnostics capability, and enhanced features over pre-microprocessor locomotives. NFORCE was developed using the latest technology specifically to allow aging locomotives to be upgraded to a level of performance matching that of their modern counterparts.

The heart of the NFORCE Control System is a powerful microprocessor that controls the various locomotive systems. The NFORCE System is based on a modular concept, in which functions can be added later without changing the entire system.

The NFORCE System can include the optional NVISION Display Panel (Operator Interface Panel), through which the complete system can be monitored or troubleshooting functions can be performed.

Primary Features...

Main Generator Control

Traction Control

Field Shunting Control

Advanced Wheel Slip/Creep Control

Traction Motor Management

Motoring & Dynamic Braking Control

Speed Indicator Drive

Automatic Sanding Control

Optional Features...

Vigilance System

Slow Speed Control

Idle Limiting Control

J1939 CAN Communications

Engine Governor Control

Radiator Shutter & Cooling Fan Control

Air Compressor Control

Automatic Ground Relay Control

Battery Charging Regulation

Contactor & Relay Control

Traction Motor Cutout Control

NVISION Operator Interface Display

Load Meter Control

NGAUGE Fuel Monitoring

NCOMPASS Wireless System

Benefits…

Initiate locomotive tests from a laptop computer or optional NVISION Display Panel (Operator Interface Panel). Operator-initiated tests include:

Contactor and Relay tests

Cooling Fan test

Self-load tests (Grids or Load Box)

Load Meter calibration and tests

Advanced wheel slip/creep control increases dispatch adhesion...

Increased adhesion results in higher starting loads and greater gross tons per mile freight haulage. Additionally, increased adhesion reduces wheel slips and spins that result in excessive wheel wear, traction motor stress and rail damage.

Motor management software calculates heat build-up in the traction motors…

NFORCE monitors loading on the traction motors, logging motor stall alarms based on software calculations. Power is reduced as needed to prevent costly traction motor damage and on-line failure.

Reduce electrical cabinet relays by up to 75 per cent…

With NFORCE’s reduced need for relays, and therefore, fewer crimp connections, the results are fewer failures resulting from poor connections, broken wires and faulty relays.

Perform and display Self-Load tests in real time…

Self-Load tests can be performed quickly. The optional NVISION Operator Interface Panel displays voltage, currents and horse power directly on the screen for immediate verification of correct locomotive loading to ensure road service locomotives operate at full power and maximum efficiency.

Optional integrated slow speed control...

Slow speed control operation is designed to run in a notch position that guarantees adequate traction motor cooling. This prevents costly damage from excessive heat build-up in the traction motors when loading in low speed operations. With an integrated system, the need for a separate – and costly – slow speed control system is eliminated.

Optional electronic engine temperature control…

NFORCE eliminates existing water manifold temperature switches, replacing them with a reliable solid-state sensor. Cooling fans are cycled to maximize operating life.

Optional integrated Idle Limiting Control reduces fuel consumption and exhaust emissions…

By monitoring locomotive operating parameters, NFORCE automatically shuts down and restarts the engine during locomotive idle times.